Any occupation that requires working at heights comes with inherent dangers, and roofing is no exception. According to the National Census of Fatal Occupational Industries in 2018 report released by the U.S. Bureau of Labor Statistics, roofing fatalities accounted for 96 of the 5,250 work-related deaths during that year.

To provide additional perspective, the fatal injury rate in the roofing industry in 2018 was 51.5 per 100,000 full-time workers, compared to only 3.5 per 100,000 in all other sectors.

These figures emphasize the importance of implementing appropriate roof safety practices for contractors and others who engage in this profession.

Roof Safety Tips

The following tips for roofing contractors can help create a safer work environment for employees.

Participate in Safety Training

If you’re a new contractor or roofing company employee, it’s crucial to receive adequate safety training before setting foot on a roof. The National Roofing Contractors Association (NRCA) offers various safety resources, including classes covering the most recent updates to Occupational Safety and Health Administration (OSHA) standards.

This training enables you to take a proactive approach to workplace safety and helps you anticipate and avoid many common rooftop hazards that can lead to injuries.

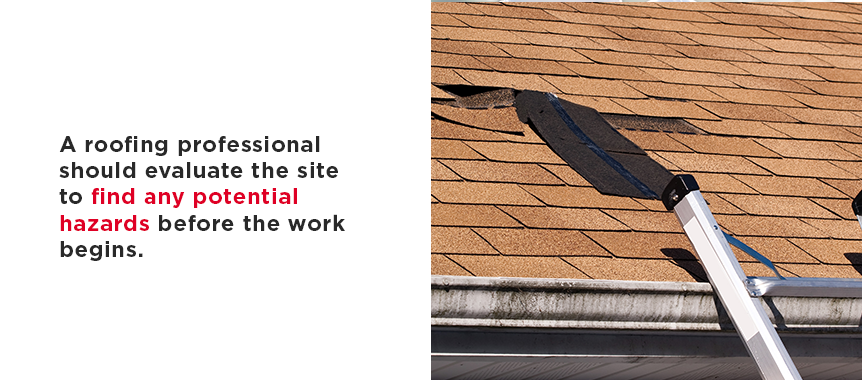

Identify and Assess the Hazards

A roofing professional should evaluate the site to find any potential hazards before the work begins. The assessment should encompass factors like the height of the structure, the roof’s pitch and angle, the presence of skylights, and the material type — asphalt shingles offer better footing than metal, for example. Once you’ve identified the hazards, you can develop a plan to control or eliminate them.

A roofing contractor should also conduct an inspection to assess the roof’s structural integrity. Older roofs, in particular, are more vulnerable to collapsing under the weight of workers, equipment, tools and materials. Checking newer structures is a good idea, as well, to ensure safety.

Pay Attention to Weather Conditions

Like any occupation that involves working outdoors, roofing can be adversely affected by the weather. Any form of precipitation can make footing on rooftops precarious and increase the risk of slipping and falling. Heavy winds can also pose a hazard, especially when sudden gusts catch workers off guard.

Protective equipment such as harnesses, anchors and lifelines are essential in these cases. Roofing contractors also can decide if they should postpone the work during inclement weather until the conditions improve. With the proper safety measures in place, working in some weather is okay. When in doubt, it’s beneficial to be cautious and wait for the poor conditions to pass before restarting the project.

In general, the beginning-of-day preparation process should always include a check of the forecast to anticipate possible changes during the workday.

Work With a Partner

You never know when something could happen while you’re working on a roof. Even a simple repair job could lead to a situation that might result in an injury. If you’re a roofing contractor, always assign at least two people to a job or take someone with you if you’re handling the project yourself. One person can “spot” the other, a proactive step that can prevent accidents. That way, if something happens, someone is there to render aid and call for assistance.

Exercise Caution When Using Ladders

Roofers spend a lot of time ascending and descending ladders. Safe practices when using these tools include:

- Set up the ladder on a flat, solid surface and secure it at the top and bottom.

- Position it to create a slope with a 4:1 ratio of 1 foot back for every 4 feet up.

- Check the ladder for any defects — loose or broken rungs, unsecured nuts, bolts or screws, or warping or rotting — before each use.

- Place ladders at least 10 feet away from electrical power lines.

- Always face the ladder when boarding and maintain three contact points — two feet and one hand or one foot and two hands — while climbing.

- Ensure the ladder’s rungs have no oil, moisture or other slippery materials on them.

- Avoid carrying awkward or heavy loads when ascending or descending.

- Never attempt to reposition a person or materials while they’re on the ladder.

- If you’re using an extension ladder, make sure to engage the locks.

- Check the ladder’s maximum load rating and stay within it.

- Adhere to the OSHA guidelines mandating fall protection systems when working on fixed ladders at a height above 24 feet.

Meet the OSHA Fall Protection Requirements

OSHA has several standards for using fall protection during roofing applications. According to an OSHA report, nearly 90% of fatal falls occur when no fall protection system is in place. All roofing professionals must institute a protection system when working at least 6 feet above the ground or at least 10 feet when using scaffolding.

Anyone performing roofing trade work should have either 100% tie-off protection, meaning they’re tethered to the roof, or install warning lines 6 feet from the roof’s edge and include fall protection extending past this boundary. You should also wear a safety harness and attach it to a permanent anchor on the roof’s edge. Consider installing netting or guardrails to provide additional safety.

Dress Appropriately

The clothes you wear can also contribute to safe roofing practices. Choose closed-toed shoes or soft-soled work boots with sufficient tread to prevent slipping. Wear outer clothing that keeps you comfortable based on the temperature but doesn’t restrict movement. A hard hat and goggles will provide essential protection for your head and eyes when working with or around roofing materials. Always wear gloves when using tools or handling materials.

All clothing should be in good repair to prevent it from getting caught on ladders, shingles, nails or power equipment.

Keep Work Areas Neat and Clean

A roof undergoing construction or repairs can quickly become littered with tools, equipment and discarded materials. Any of these objects can create a tripping hazard. The best practice is to organize and clean all areas as you go instead of waiting for the debris to pile up. You’ll experience a safer work environment, and the absence of clutter will enable you to perform your duties more efficiently and productively.

Eliminate Distractions

Too often, workplace accidents occur because workers are paying attention to something other than the task at hand. Roofers who are distracted could easily trip over an object or slip off the roof. Roofing contractors can implement steps that keep these situations from occurring, such as prohibiting smartphone use on the job site unless using it for work-related purposes. Another option is to have someone on the ground relay messages.

Avoid Working While Impaired

Even a slight loss of balance can have harmful consequences when working on a roof. Roofing contractors should have a strict policy prohibiting alcohol or recreational drugs on the job. Many prescription medications can also cause dizziness, lightheadedness or drowsiness — anyone taking them should consult with their physician to ensure their safety before climbing onto a roof.

Dehydration can be an issue, as well, when working on a rooftop in the summer. Workers should drink plenty of water throughout the day to prevent this potentially dangerous state. In addition, workers with vertigo should cease work until their condition improves or consider changing professions for their safety.

Use Nail Guns Safely

A pneumatic nail gun is a vital tool in any roofer’s arsenal. It can also be dangerous unless the operator handles it with care. Safe practices when using nail guns include:

- Never point the tool at another worker, even if you believe it doesn’t contain any nails.

- Check the device before each use to ensure it’s working correctly, including inspecting the safety mechanism.

- Only pull the trigger when pressing the firing end against the material you’re fastening.

- Select the full sequential trigger option to reduce the risk of double-firing an unintentional nail discharge.

- Avoid leaning the tool against your body, as this action could cause the gun to misfire accidentally.

- Always disconnect the gun from the air supply when you’ve finished the job, and never attempt to perform maintenance or repairs on the tool while it’s connected.

- Wear appropriate personal protective equipment (PPE) such as hard hats, safety goggles, and earplugs or muffs whenever operating nail guns.

Regardless of the tool, all workers should receive adequate training to use the equipment efficiently, productively and safely. They should also have access to the PPE suitable for the device and application.

Deploy Covers

Roofs may contain skylights or have holes or openings that create a fall hazard. Applying covers can eliminate this risk. According to OSHA, all covers used in roofing applications should have the following characteristics:

- Ability to support at least twice the weight of any workers, tools and materials that may fall onto the cover at any given time

- Sufficient securing to prevent the wind from blowing it away or workers or equipment displacing it

- Color coding or marking with words like “hole” or “cover” to warn everyone of the hazard

Debris Disposal Practices

Roofing projects generate an abundance of discarded materials and other waste products that require proper, safe disposal. Removing these items can be challenging, as workers can trip and fall over loose objects or accidentally drop them on people on the ground.

An OSHA-recommended debris removal practice for roofing work entails using a forklift to raise a trash collection box to the roof’s level, allowing workers to fill it with debris. The forklift can then lower it to the ground and enable a truck to transport it to the dumping site. This procedure also saves time and increases efficiency.

Working With Hazardous Materials

Some roofing jobs could expose workers to hazardous substances, including asbestos, lead or silica. These materials and several others can cause significant health issues. Asbestos exposure, for example, could result in cancer or a potentially fatal loss of lung function.

Roofing contractors and employers should be aware of the possible presence of these substances, especially when working with older roofs constructed before the awareness of how dangerous these materials can be. Ensure you implement the proper procedures to keep workers safe.

Collaborate and Coordinate With Other Contractors

Construction jobs often involve multiple contractors — roofing, HVAC, electrical, plumbing, carpentry, etc. — to handle the project’s various aspects. Some of these functions coincide, which can pose safety issues.

All contractors must coordinate their efforts to ensure everyone is on the same page throughout the process. These steps can reduce the risk of workplace accidents, such as workers being struck by mobile equipment or falling debris because they are unaware of the hazards near their work area.

Develop an Emergency Action Plan (EAP)

Workers must know what to do whenever a safety-related emergency occurs during a roofing project. Employers should create a comprehensive EAP that complies with OSHA standards. They should inform workers of the site’s street address so they can relay it to 911 staff when calling for assistance. Also, someone with first-aid training should be available at the site and have access to supplies to address situations like eye exposure to corrosive materials.

Establish a Safety Culture

Roofing contractors and construction industry managers are responsible for keeping workers safe at the job site. Instilling a safety mindset is crucial for ensuring everyone makes safety a top priority.

A culture of safety starts by setting the tone at the top. Managers should lead by example by following all established procedures and encouraging workers to do the same. They should provide regular, ongoing training to ensure employees understand the expectations regarding safe practices while on the job.

Companies should also develop and implement a positive reporting process to encourage workers to speak up about safety concerns. Offering rewards or incentives for doing so can make employees feel more comfortable about coming forward.

What Are the Benefits of Enhanced Roofing Safety?

Implementing these roof installation safety tips can provide numerous benefits for your business:

- Reduction in workplace accidents that cause significant injuries

- More productivity due to fewer workers missing days because of injuries

- Decrease in costly workers’ compensation claims

- Happier workers who recognize that their employer is taking steps to protect them while on the job

- Reduced risk of liability issues that could lead to expensive lawsuits and damage to a company’s reputation

- More efficient, streamlined work processes resulting in better quality services

Contact Dataforma for More Roof Repair Safety Tips

A roofing contractor founded Dataforma in 2003 to provide a robust software solution for roofing, HVAC, plumbing and other construction industry professionals. We create innovative customer relations management (CRM) systems that enable businesses of all sizes to keep track of their data and communicate with customers more effectively. Our products can improve document storage, lead tracking, project scheduling, paperless service management and much more.

Dataforma can also help your business with our unwavering commitment to delivering superior customer care. We provide comprehensive training and ongoing support for all our products, enabling you to maximize your return on investment. We also listen to our customers — we appreciate and encourage feedback and use it to improve the quality of our services.

Discover how Dataforma can help your roofing business move forward. Call us at 866-211-9424 today for more information or contact us online to request a free software demo. We’ll also be happy to provide additional helpful roof safety tips.